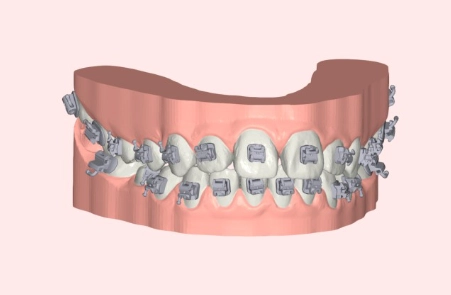

Custom Appliances. Digitally Designed. Perfectly Made.

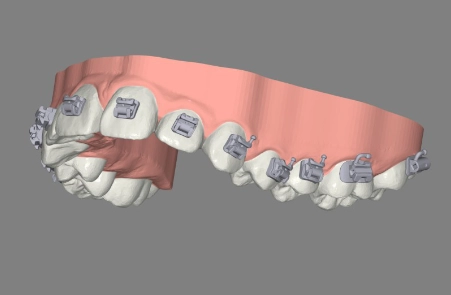

We use advanced digital design and production methods to create removable and fixed orthodontic appliances — tailored precisely to your smile.

Discover Our In-House Lab →Less guesswork. More precision. Better results

Digital manufacturing lets us design every appliance — from aligners to expanders — with complete control and clarity. It means better fit, more comfort, and fewer surprises.

Smarter Diagnostics

The Technology Behind Your Smile

We use cutting-edge tools to track your jaw and bite in real time — helping us plan treatments that not only look great, but feel right too.

Our Features

Benefits for You

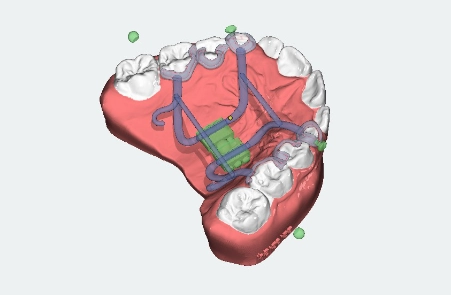

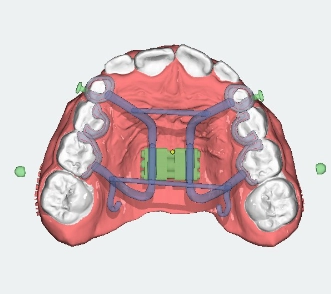

Smart Printing at Every Step

How we turn digital models into perfectly crafted orthodontic devices—accurate, comfortable, and fast.

Start Your JourneyDigital Design

We plan your appliance digitally, using your 3D scan to guide exact sizing, shape, and placement.

Virtual Modeling

Each device — whether it’s a night guard, expander, or aligner tray — is designed with precise, patient-specific parameters with our holistic KFO360° concept.

High-Tech Fabrication

Your appliance is produced via 3D printing, laser sintering, or CAM milling, depending on the material and use.

Fitting & Fine-Tuning

We check the fit and make any last micro-adjustments so everything feels great from day one.

Every Step Counts

From digital scans to handcrafted aligners – we combine precision, care, and experience at every stage of your orthodontic journey.

Tailored Devices for Every Need

We use digital device manufacturing across all types of orthodontic appliances — from expansion plates to splints and retainers.

Testimonials

Tech That Made a Difference

Patients often tell us how much more comfortable their devices feel — and how quickly everything was ready.

Frequently Asked Questions

What types of orthodontic devices can be made digitally?

We use digital manufacturing for a wide range of devices — including aligners, retainers, expanders, night guards, and more. Both removable and fixed appliances are designed with precision.

How is digital manufacturing different from traditional methods?

Traditional models are made by hand, which can lead to small errors. With digital technology, every device is modeled on your exact scan — meaning better fit, comfort, and fewer adjustments.

Does it take longer to produce a device this way?

Not at all! In fact, digital production often speeds things up. Once we’ve planned everything virtually, devices are printed or milled quickly — with less waiting for you.

What happens if I lose or break my device?

Since your model is saved digitally, we can reproduce it quickly without starting over. No need for a new scan or impression.

Are digital devices more expensive?

Not necessarily. While the tech behind it is modern, efficient processes often balance out costs — and save time, appointments, and follow-up visits in the long run.